Uncategorized

DATALOGIC MEMOR 1 OPENS NEW DOORS FOR ERP SUPPLIER HYDRO WEST

New product allows more dynamic and interactive apps from Bever Automation

As one of the first Datalogic partners, Bever Automation has been using the Memor X3 for many years. At the beginning of 2020, Bever Automation switched to the Memor 1, enabling them to make their apps even smarter. Doors that until recently remained closed are now opening and Bever Automation’s customers are the main beneficiaries of this.

For 30 years, Bever Automation has been developing and supplying ERP software for companies involved in the sale and repair of products in machine engineering. “Our customer base is very varied”, says Gijsbert Flier, Operations Director at Bever Automation. “From agricultural mechanization, milk production and internal transport to technical wholesalers and companies in the truck and trailer sector. Wherever service to machines and installations is central, our solutions offer added value”.

Barcoding as a common theme

Since the very beginning, Bever Automation pioneered the use of barcoding solutions. Flier says: “We were the first in our industry to offer companies the opportunity to register items on work orders using barcoding. At the time we called it “Simple Writing”. And Bever Automation still knows how to optimize customer processes using barcodes. “For a long time now, it’s no longer just about registering work orders, barcoding is also a common thread for many business processes including inventories, for example transfers from the main warehouse to the service buses, and purchase registration”, says the Operations Director.

Even smarter

Bever Automation has been supplying scanning solutions with Datalogic products for more than ten years, including the Datalogic Memor X3. Recently Bever switched to the Datalogic Memor 1. Where the Memor X3 runs on Windows CE, the Datalogic Memor 1 runs on Android, which opened doors that previously remained closed. “Android makes it possible for us to make our apps even smarter. The combination of the new app and the Memor 1 from Datalogic not only offers advantages for us, but also for our customers”, says Flier.

Practical benefits

One of those customers is Hydro West in Zwaag. The hydraulics specialist has been working with Bever’s solutions for over twenty years. “We use almost the complete package; for financial affairs and counter work, but also for logistics and work orders”, says Richard van Rijn, who is responsible for business development and logistics at Hydro West.

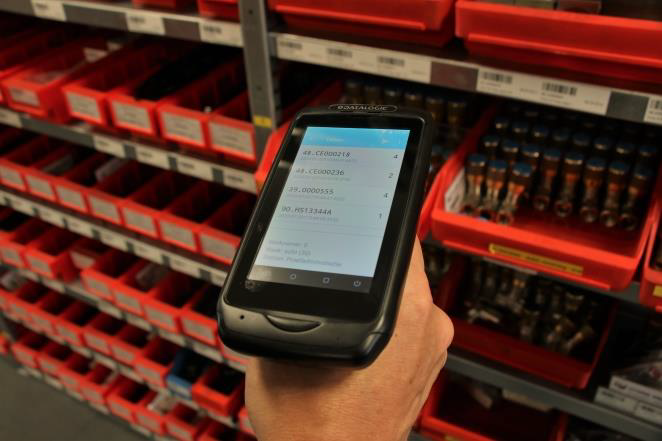

At Hydro West, the scanning solutions are mainly used to count stock and raise work orders. The Memor 1 offers definite advantages in this respect, according to Van Rijn: “The Datalogic Memor 1 screen is significantly larger and can display much more information. At a glance you have all the information you need; clear and organized. Moreover, because the system works on Android, it is more recognizable for our employees. Everyone has Android on their mobile. This makes the solution intuitive and easy to use. This also minimizes learning time for new employees.

Additional benefits

Android also makes it possible to remotely support or set up new scanners. Scanning a few QR codes is enough to install software or software updates. The only thing customers must do themselves is to set up the right Wi-Fi network.

Compared to its predecessor, the Datalogic Memor 1 offers additional advantages. The larger display is full touch and thanks to the built-in imager, 2D codes can also be scanned. “Barcode scanning is also much faster,” adds Flier. The Datalogic Memor 1 is also compact and easy to hold in your hand. A pistol grip version – ideal for use in situations where large quantities of barcodes need to be scanned – is also available.

New app

To ensure that customers can continue to work flawlessly with the Memor 1, Bever Automation has developed a new app, which will be further updated in the near future. “With new functionalities and extra tools, we want to optimally meet the wishes of our customers”, says Flier.

Hydro West has already discussed its wishes with Bever. “We know from experience that they listen carefully and proactively think about result-oriented solutions. I am convinced that they will come up with a suitable solution again and that we will be able to optimize our processes even further in the future”, concludes Van Rijn.

Going forward

Although Hydro West has been working satisfactorily with Bever’s solutions for years, Van Rijn still has a few wishes: “We would like to see the scanning solution more dynamic, so you can see live in your system what’s happening on the floor”.

“That dynamism is a good example of the new possibilities,” adds Flier. “Because the Memor 1 runs on Android, we are able to retrieve data in real time from our ERP package PowerAll and the interaction increases. When you scan an item with the Memor 1, all relevant information is immediately available. Scanned articles can also be added directly to a work order, and multitasking is possible. For example, if during scanning it appears that the stock deviates, it can be adjusted immediately. In addition, the network connections are much more stable. “The chance that you will drop out of the network while working is virtually zero”, Van Rijn noticed.